In the world of trucking air springs and shock absorbers go hand in hand.  Air suspensions cushion the ride for drivers, passengers, vehicles, and loads. The air springs and shock absorbers are the two main components that help control the movement of the bags and the suspension. Since these two components are used regularly they need to be inspected and repaired on a regular basis to prevent wear and aging.

Air suspensions cushion the ride for drivers, passengers, vehicles, and loads. The air springs and shock absorbers are the two main components that help control the movement of the bags and the suspension. Since these two components are used regularly they need to be inspected and repaired on a regular basis to prevent wear and aging.

When to Change Air Springs?

Air bags are made of rubber causing them to age or wear out. If the truck is normally drove in an environment with lots of heat it can cause this process to speed up. As the air bags age, it is common for cracking and horizontal splits in the rolling lobe to occur. The rolling lobe is a part of the air spring that is under the most stress. When cracking begins it doesn’t always mean the air springs are leaking. The cracks usually occur in the outer layer. The outer layer tends to occur before the inner layer; which is where leaks occur.

When horizontal cracking happens, this is an indication that the aging process is advanced, and the air springs need changed. The age of the air springs can be checked by reading the date code on the air springs. If they are older than five years, it is usually time for a change.

Are the Shocks Working?

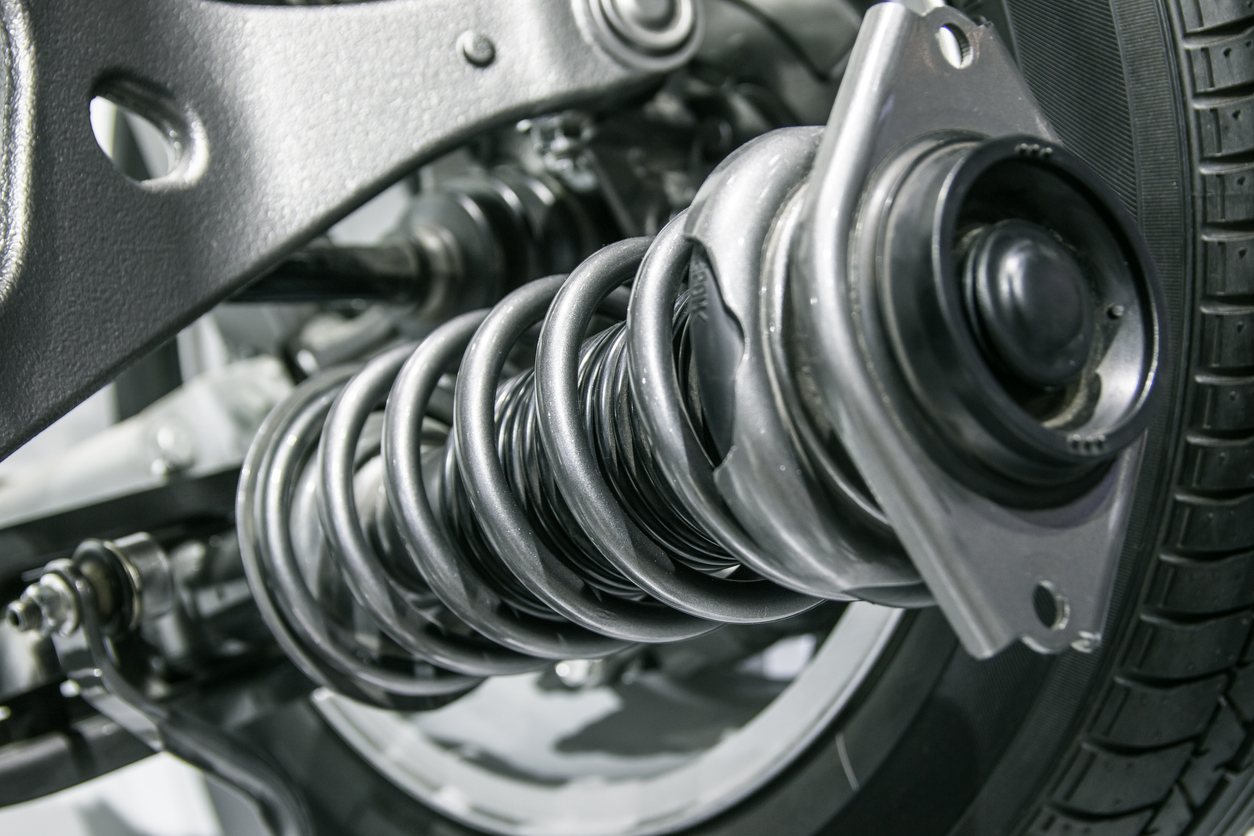

Shock absorbers are used to minimize wear and protect suspension components from vibration damage. The most common cause of air spring failure is overextension, caused by improper functioning shock absorbers. Making sure the truck shock absorbers are in good working condition is vital.

Signs that the shocks should be replaced:

- Uneven tire wear

- Ride deterioration

- Excessive vibration

- Sagging taper leaf springs

- Premature wear

- Broken or torn air springs

Checking to see if the shocks are working can be as simple as taking the truck for a drive and checking to see if the shocks are warm or hot. Both sides of the vehicle should be checked at the same time. Shocks should be warmer then the frame rail and should be close to the same temperature as the other. Some truck owners recommend using an infrared temperature gauge. If there is a greater difference than 20% between the two, the shocks would need to be removed to closer examine.

After removing the shocks to check for further damage, turn the shock upside down and shake them. Listen for a rattling sound which would indicate a broken piece on the inside. Stroke the shock in the upright position to check for resistance. The shock should return to full height position after release. Both shocks should be replaced at the same time to keep performance equal.

Keeping your truck in top maintenance will help save on unexpected costs and downtime. Air springs and shocks are often forgotten until there is an issue. Get into a routine of checking them at each oil change, this will help you develop a routine and minimize surprises later.

The job of every commercial vehicle driver is not just to get their load to the destination in time. ...

The job of every commercial vehicle driver is not just to get their load to the destination in time. ...